Material Science Expertise

The development, testing, and enhancement of high-performance aluminium casting solutions

Grainger & Worrall's engineering function specialises in the development, testing, and enhancement of high-performance aluminium casting solutions tailored to each customer’s operational requirements. Whether you're optimising for ductility, strength, thermal stability, or even sustainability, our materials team can provide support and consult on materials selection and optimisation.

Materials Capability: Matching Alloys to Performance Requirements

Get components that perform reliably in your specified conditions, with the opportunity of casting integral products using either aluminium-silicon alloys or aluminium-copper alloys, from conventional grades like A356.2 up to motorsport/aerospace alloys such as 201.

We carefully select aluminium alloys to achieve product requirements, engaging early in the design phase to ensure a balance between material and functional design. We optimise processes for superior, reliable material properties. This is also closely linked to our simulation capability, ensuring alignment between simulation and actual.

Alongside industry-standard grades, we’ve developed proprietary alloys designed for demanding use cases, including elevated-temperature environments.

Flexible Casting Processes To Match Project Demands

We offer both counter-gravity sand casting and low-pressure sand casting (specific alloy) and can develop novel solutions, giving you the flexibility to match the right process to your project’s performance, geometry and cost requirements.

Aluminium Alloys

Our growing selection of aluminium casting alloys includes BS EN 1706, AMS and ASTM type equivalents, laying a reliable foundation for a wide portfolio offering of high-performance casting alloys. As well as our own internally developed alloys. We have extensive experience in the following specified alloys:

-

300 Series: 356, 357, 354, 355, 356 + 0.5%Cu, AlSi9Mg (Image to the left)

-

200 Series: 201, 206, L119/RR350

We also offer additional grades on request to meet your exact needs. With experience across most industrially recognised alloys, we ensure material compatibility no matter how complex or regulated your application.

.png?width=957&height=688&name=Image%201%20(3).png)

Secondary Alloys

Using secondary alloys reduces waste, promotes resource efficiency and cuts carbon emissions by avoiding the energy intensity of primary aluminium production, all while maintaining the performance your components demand.

In addition to recycling in-house, we work with suppliers that provide ingots produced from high levels of externally sourced secondary aluminium, fully characterising each batch to ensure consistent casting quality.

While recycled aluminium can match the strength and durability of primary material, it often carries impurities like oxide and iron intermetallics. We overcome these with advanced characterisation, composition control and proprietary metal preparation, allowing us to deliver high-integrity castings that meet performance and sustainability goals.

Heat Treatment Facility

Heat treatment (HT) of aluminium alloys enables the functional performance potential of aluminium sand castings. We deliver on-site heat treatment to internal and customer specs and work with approved suppliers for automotive and aerospace process requirements, e.g. Hot Isostatic Pressing (HIP), a process that enhances material density and eliminates porosity.

Our AMS2750-certified aerospace facility delivers precise, repeatable heat treatment. We use drop quench technology to improve metal quality properties, supplemented by using polymer quench media to minimise casting distortion and residual stress. This keeps components dimensionally stable compared to conventional processes, e.g. hot water quench. Our facility's process parameters are all recorded to ensure repeatable process control, ensuring the highest quality for our customers.

HT Facility Equipment includes

-

1x Materials Research HT Oven

-

2x Solution HT Furnaces (2.15m x 2.15m x 2.5m)

-

2x Precipitation Age Ovens

-

Bespoke setting processes

-

Industrial freezer incubation

HT Process Capability

-

T4 heat treatment - Solution treated and naturally aged to a stable state.

-

T5 heat treatment - Cooled from elevated temperature, then artificially aged.

-

T6 heat treatment - Solution treated and artificially aged (includes T64).

-

T7 heat treatment - Solution treated and overaged.

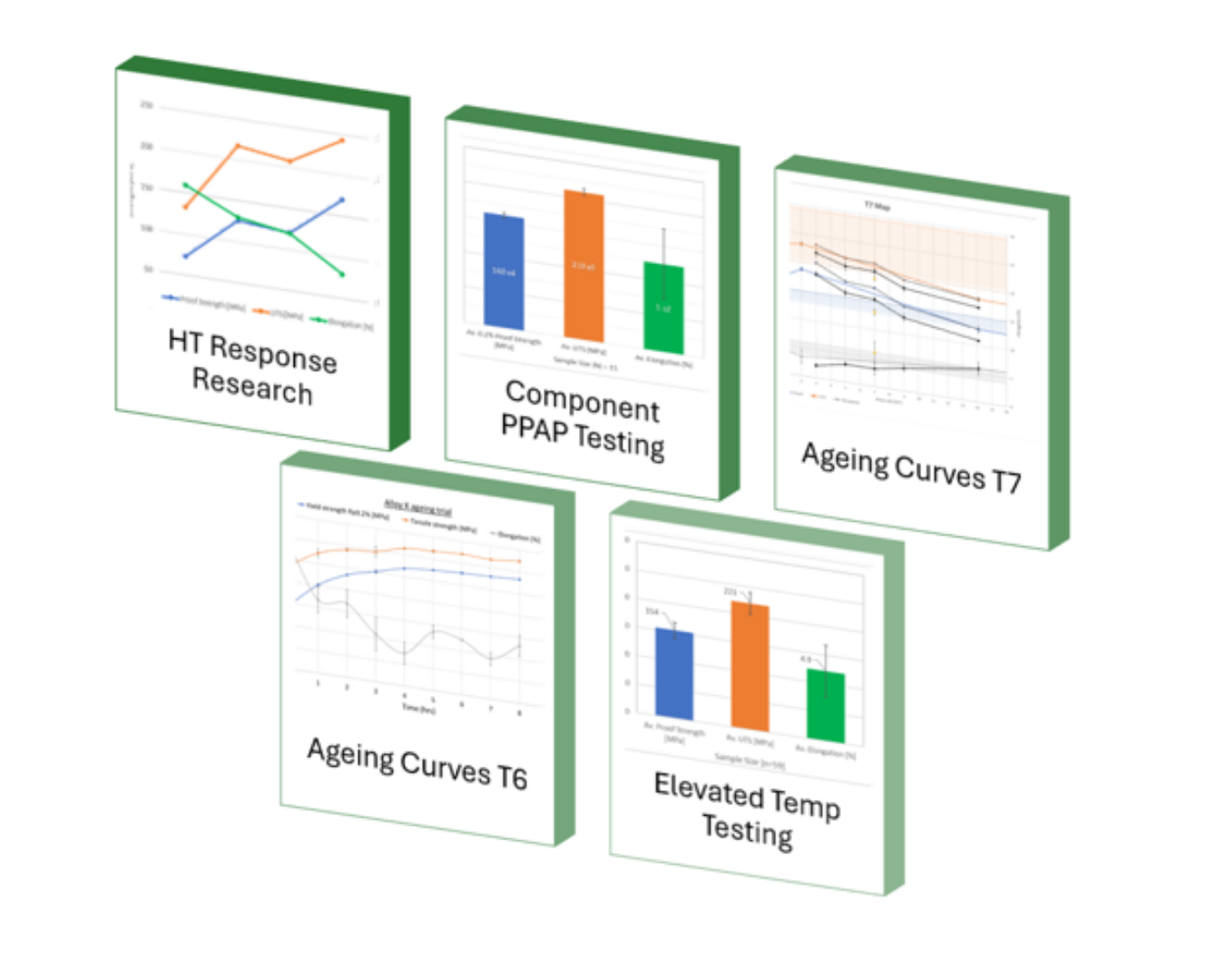

Assessing Capability

Aluminium castings properties are heterogeneous (not uniform), so it's critical that materials are characterised to ensure properties are met and exceeded where required.

We utilise our extensive catalogue of empirical material properties, from actual castings to support our customers. This includes:

-

Mechanical properties – Room Temperature

-

Property mapped components

-

Elevated temperature mechanical properties

-

Fatigue studies

-

Thermal properties

-

Niche properties e.g. growth stabilisation

Laboratories

Metals Laboratory

Metallurgical testing helps us assess the microstructural characteristics of aluminium castings so we can optimise the material quality and performance.

Capabilities include:

-

Mechanical property mapping

-

Failure analysis and defect detection

-

Microstructural evaluation

-

Quality and specification compliance

-

Comprehensive reporting and validation

Sand Testing Laboratory

We support Silica, Cerebead, Zircon and Bauxite sand systems with full lab analysis, including:

-

pH testing

-

Permeability and strength tests

-

Rapid LOI

-

Particle/grain size analysis

These tests help maintain moulding media quality and control process variables, ensuring your components meet specifications. We also collaborate with our rapid prototype sand printing team to stay ahead of material and process legislation.

Spectrographic Laboratory

Our spectrographic lab verifies the precise chemical composition of aluminium and ferrous alloys, ensuring traceability and compliance with your specifications.

Capabilities include:

-

3x Bruker OES spectrographs

Conforming to ASTM E1251

We regularly analyse melt samples during production, as per the control plan, to ensure accurate measurement.

Mechanical Testing Laboratory

Mechanical testing validates the strength, durability and functional performance of our cast components.

We work with a third-party, UKAS-accredited on-site lab for all mechanical testing. They conduct all our tests according to BS EN ISO and ASTM standards to guarantee impartial, accurate verification of casting quality.

Innovation Strategy Summary

Strategic collaboration is essential for us. We actively participate in initiatives like Innovate UK and the Advanced Propulsion Centre (APC) government-funded programmes. These help us stay ahead of evolving industry needs in aluminium casting and beyond.

SO, WHAT ARE YOU WAITING FOR...

Want to get a clearer understanding of the sand casting process?

Download our FREE ebook on "The basics of the sand casting process" and get an overview of how battery trays, EDU housings, and other complex shapes can be cast in Aluminium or Ferrous alloys.

Get in touch

Get in touch