Sand castings to power ICE and EV Automotive.

Grainger & Worrall produce high-precision, flexible and fast sand castings for ICE and EV automotive components.

LIGHTWEIGHT, PRECISE CASTINGS FOR MODERN ICE AND EV AUTOMOTIVE.

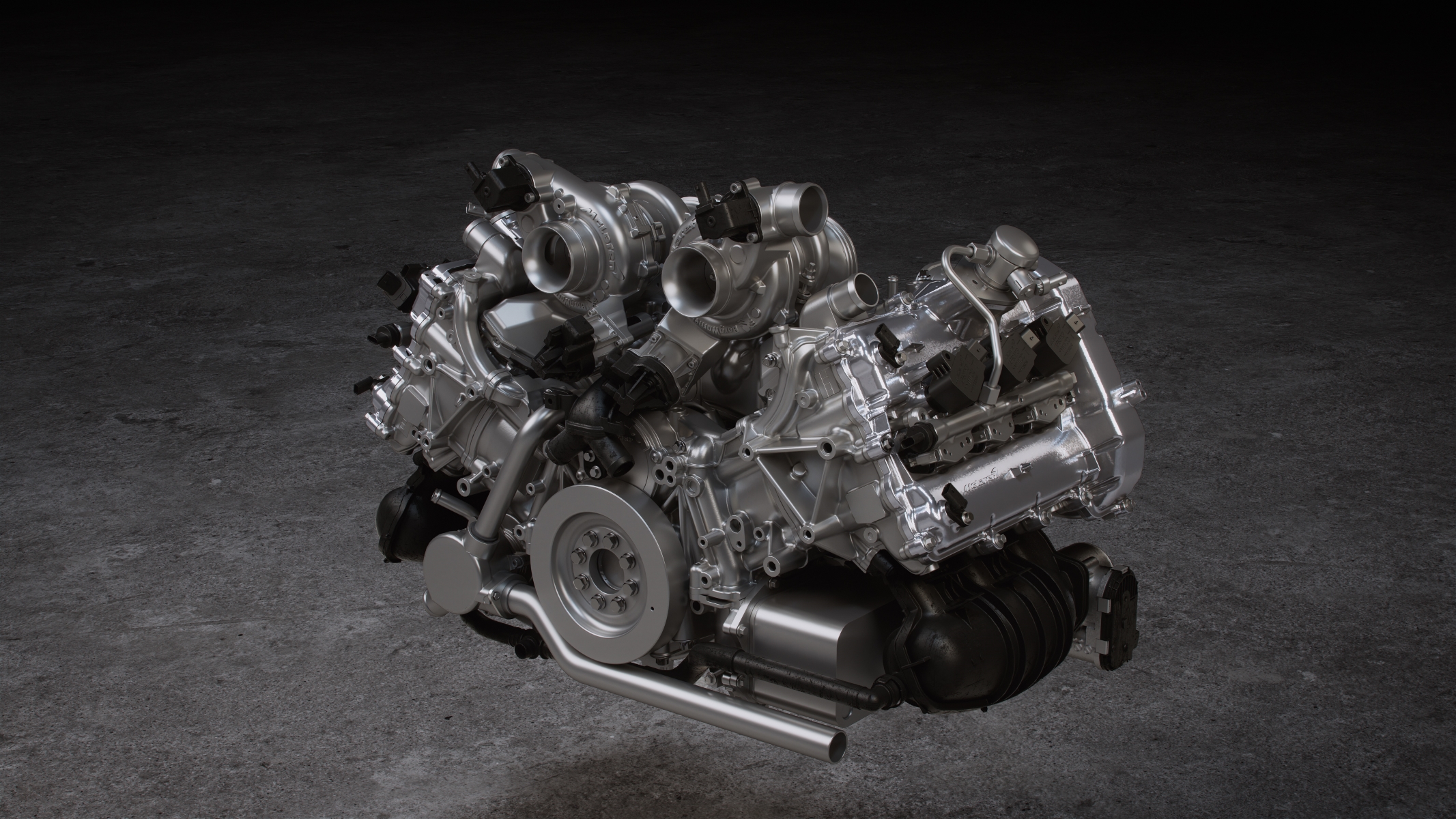

At Grainger and Worrall, we create the high-integrity, lightweight aluminium sand castings demanded by the automotive industry for ICE and EV powertrain components.

We use our sand casting expertise, as well as materials knowledge to create bespoke aluminium alloys that are strong, light and precise, driving modern applications. And we do it accurately and fast. Every time.

PRECISION ICE AUTOMOTIVE SAND CASTINGS, FROM FIRST CONCEPT THROUGH TO PROVEN CONCEPT.

We specialise in manufacturing high-quality aluminium sand castings that meet exacting automotive industry demands for complex powertrain components. Our sand casting expertise combined with our materials knowledge enables us to produce customised aluminium alloys that are strong yet lightweight. Our rapid and accurate production process ensures consistent quality with every casting.

EXPERTISE IN SAND CASTING FOR AUTOMOTIVE APPLICATIONS YOU CAN RELY ON.

-

We develop specific and bespoke alloys that retain their mechanical properties in temperature-critical applications, crucial to match ICE engine temperature increases

-

We produce high-integrity and high-performance sand castings for ICE and EV that allow us to supply series and prototype engine components which model production parts with MLP production properties.

-

We work with our automotive customers to solve complex problems with innovation and prototyping expertise in sand casted powertrain components.

-

We use inspection techniques such as CT scanning and GOM measurement to ensure we meet tight tolerance specifications and requirements, delivering high integrity castings every time.

-

We’re able to reduce time-to-market for compressed lead times with innovative techniques and technologies to speed up manufacture, such as 3D digital sand printing.

-

Bespoke alloys and ability to create complex, net shapes with sand casting allow us to meet lightweighting and part count reduction demands in automotive components.

-

Our sand casting expertise adds value at every stage of development, including in prototyping, initial concepts and proof of concept.

-

Lightweighting Through Efficiencies

G&W is working in partnership with major vehicle OEMs to develop lightweight chassis, powertrain and drivetrain components. We've developed a fast and reliable method for casting hollow aluminium components, at a lower cost compared to traditional hard tooling.

Lightweighting has always been integral to vehicle design, but it's now even more essential due to the implementation of new electrification strategies - contributing to increased battery range.

Read more in the case study here.

-

Engine Block Innovation

G&W worked with the ALIVE6 team, and in conjunction with Jaguar Land Rover (JLR) and Advanced Propulsion Centre (APC) to develop a casting process and supply chain to support leading-edge technology that developed a new type of cylinder block that used plasma coatings to reduce the weight and size of engines.

This required exploring elements such as the structural strength of the cylinder, as well as the porosity and adhesive properties of the alloys.

Read more on the case study here.

-

Cylinder Head for Historic Volvo Range

Grainger & Worrall partnered with a leading Swedish engine designer to recreate a twin-cam, 16 valve engine for use with historic Volvos. The twin-cam unit, originally developed in 1971, was produced with the latest engine design capabilities and sand casting techniques. It is for use with Volvo models such as the P1800, 140, 142 and 145, as well as the PV544.

Read more in the case study here.

Innovation meets Quality

Grainger and Worrall are passionate about innovation and quality. It impacts everything we do. Whether it's innovating with rapid prototyping, or driving lightweighting for lighter, more durable F1 engines, we make sure each and every part is fit-for-purpose and meets the quality specifications our customers expect. But don't just take our word for it, check out our accreditations below.

SO, WHAT ARE YOU WAITING FOR...

Want to get a clearer understanding of the sand casting process?

Download our FREE ebook on "The basics of the sand casting process" and get an overview of how battery trays, EDU housings, and other complex shapes can be cast in Aluminium or Ferrous alloys.

Get in touch

Get in touch